2026 Best High Speed Inspection Machine Features and Benefits?

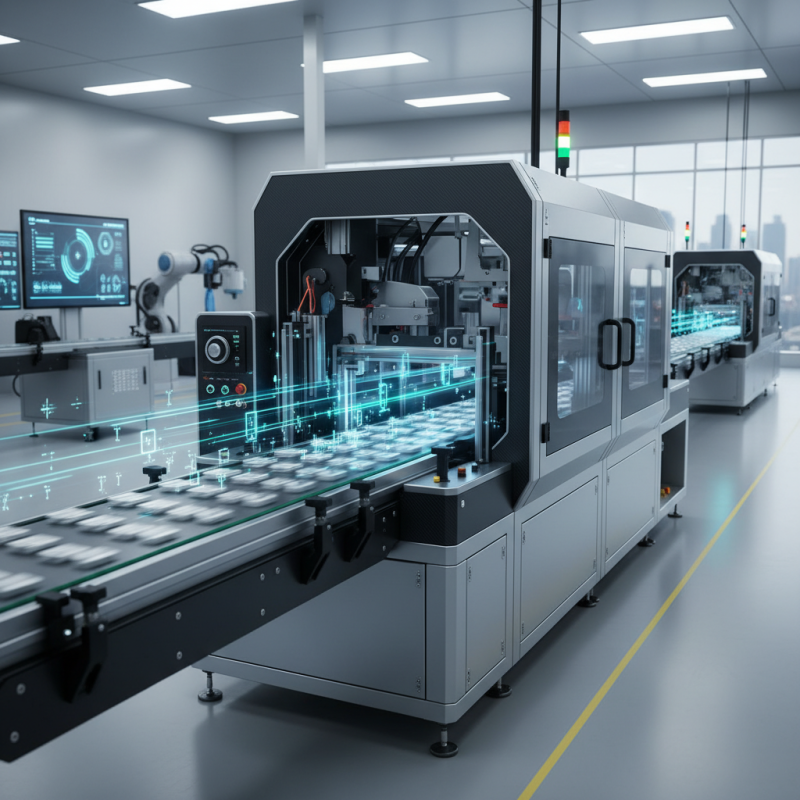

In the fast-paced world of manufacturing, the demand for High Speed Inspection Machines is rising. Reports indicate that the global inspection machine market is projected to grow by 8% annually. This growth reflects the need for efficient quality control in production lines. High speed inspection technology plays a crucial role in this context.

Such machines can process thousands of products per hour, significantly reducing inspection time. Their ability to detect defects early enhances product quality and minimizes waste. However, challenges remain. Not all High Speed Inspection Machines can meet the evolving needs of various industries. Companies must carefully assess features, such as precision and adaptability, before investing.

Integration with existing production systems is often overlooked. As industries adapt to newer technologies, this integration becomes pivotal for success. Moreover, regular maintenance practices are essential to maximize machine performance. The future of High Speed Inspection Machines holds promise, but only with careful consideration of their functionalities and real-world application.

Key Features of High-Speed Inspection Machines

High-speed inspection machines have become essential in various industries. These machines offer a swift and accurate way to check product quality. One key feature is their advanced imaging technology. This allows them to capture detailed visuals of products in real time. The speed of inspection can reach thousands of items per minute. This reduces bottlenecks in production lines.

Another notable feature is the integration of artificial intelligence. AI can help identify defects quickly and reliably. It enhances performance by learning from past inspections. However, not every AI system is flawless. Some may misinterpret data, leading to false positives or negatives. This aspect needs careful consideration while deploying such machines.

Additionally, user-friendly interfaces are vital. Operators should be able to navigate the system with ease. Complex settings can result in errors. Maintenance is also a crucial factor. High-speed machines can require frequent checks to ensure optimal functioning. Neglecting maintenance can lead to costly downtimes. Thus, while these machines offer many advantages, continuous improvement and review are necessary for effective operation.

2026 Best High Speed Inspection Machine Features and Benefits

| Feature | Description | Benefits |

|---|---|---|

| High-Speed Throughput | Capable of processing up to 3000 units per hour | Increased production efficiency and reduced costs |

| Advanced Imaging Technology | Utilizes high-resolution cameras for detailed inspection | Improved defect detection and quality assurance |

| Flexible Configuration | Adaptable to various production line setups | Easier integration into existing processes |

| User-Friendly Interface | Intuitive controls and monitoring system | Reduced training time for operators |

| AI-Based Analytics | Utilizes artificial intelligence for predictive maintenance | Minimized downtime and maintenance costs |

| Compact Design | Space-efficient layout for limited production areas | Versatile installation options and reduced footprint |

Advantages of Implementing High-Speed Inspection Technology

High-speed inspection technology is revolutionizing quality control. This leads to significant advantages for manufacturers. Studies show that implementing such technology can increase efficiency by up to 30%. This allows companies to detect defects earlier in the production process. As a result, businesses save costs by reducing waste and rework.

Automation is a crucial element here. Fast inspection machines can perform thousands of checks per minute. This level of precision minimizes human error. A report from an industry leader indicated that error rates drop by over 50% when using automated inspection systems. However, reliance on technology also raises concerns. For instance, machines may misinterpret anomalies or require frequent calibration.

Balancing efficiency and cost can be tricky. While high-speed inspection systems offer speed, they also demand a significant upfront investment. Businesses should weigh these factors carefully. Adopting this technology is not just about quick fixes; it requires strategic planning. Understanding both benefits and drawbacks is essential for sustainable success.

Comparison of High-Speed Inspection Machines on the Market

High-speed inspection machines play a critical role in various industries, from pharmaceuticals to electronics. A recent industry report noted that these machines can achieve inspection speeds exceeding 500 products per minute. This efficiency is crucial in high-volume production environments where even minor errors can lead to significant financial losses.

Comparing the current high-speed inspection machines on the market reveals diverse features. Some prioritize advanced imaging technology, while others focus on speed and adaptability. According to a market analysis, 75% of users reported decreased downtime with machines that employ AI algorithms for real-time defect detection. However, some operators struggle to adapt to these technologies, pointing out a gap in training and comprehension.

Another aspect to consider is maintenance. Around 40% of facilities experience frequent breakdowns due to insufficient upkeep. While manufacturers boast about speed, the actual reliability appears inconsistent. This inconsistency raises questions about whether speed should take precedence over durability. Investing in inspection machines that strike a balance between speed and reliability remains a key area for reflection.

Applications of High-Speed Inspection Machines in Various Industries

High-speed inspection machines have become vital in various industries. They enhance quality control by quickly identifying defects. In packaging, these machines inspect labels and seals. A minor flaw can lead to significant losses. Speed and accuracy matter in this field.

In the pharmaceutical sector, high-speed inspection machines are crucial. They check for proper labeling on bottles and boxes. Any missed error can affect patient safety. However, the technology isn't flawless. Sometimes, machines may misidentify products due to similar packaging designs.

Food production also benefits from these machines. They ensure that products meet safety standards. Inspecting expiration dates and package seals is essential. But, over-reliance on automation can cause lapses. Human oversight remains necessary. Balancing technology and human judgment is key to maintaining quality in production lines.

Future Trends in High-Speed Inspection Machine Development

The future of high-speed inspection machines is rapidly evolving. With advancements in technology, these machines are becoming more efficient and accurate. By $2 billion, it is projected that the global market for high-speed inspection machines will reach 2026, growing at a CAGR of 8%. This growth can be attributed to the increasing demand for quality assurance in various industries.

Tip: Regularly assess your inspection processes. Look for areas needing improvement. Implementing new technology can lead to significant advancements.

Material advancements also play a critical role. Lightweight materials are being used to reduce machine wear and tear. This shift can enhance the longevity of inspection machines. However, there's a need for careful evaluation of material performance under high-speed conditions.

Tip: Consider testing new materials before widespread implementation. It's crucial to understand both benefits and limitations.

As high-speed inspection technology progresses, organizations must stay ahead. Balancing innovation with practical application will be key to thrive in this dynamic landscape.