What are the Benefits of Enameled Aluminum Wire in 2026?

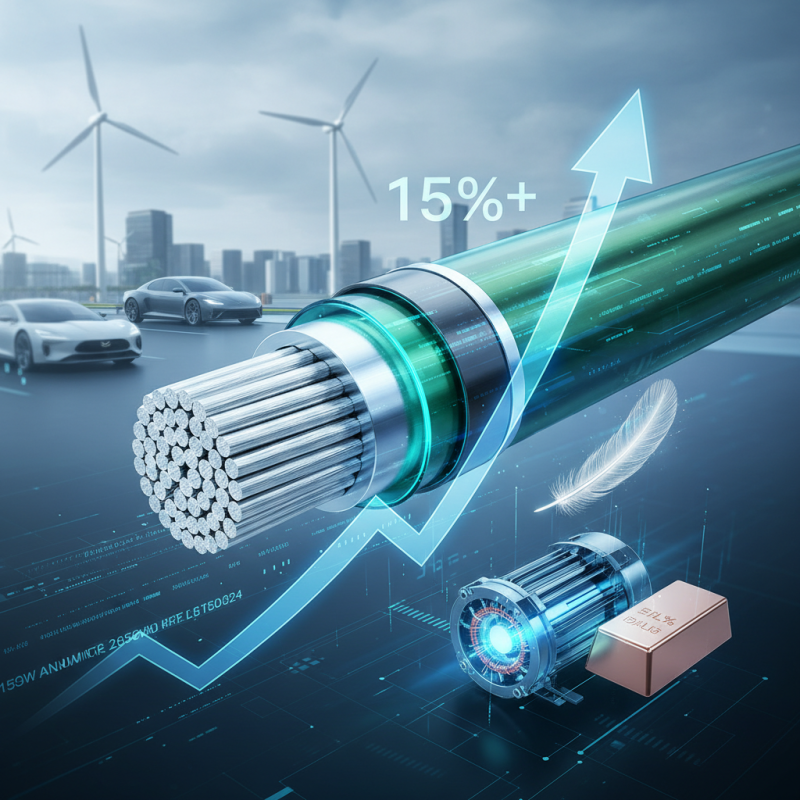

In 2026, the use of Enameled Aluminum Wire is set to soar, driven by advancements in technology and sustainability. Experts predict that the market for this wire could grow by over 15% annually. One industry expert, John Stevens, noted, "Enameled Aluminum Wire provides unmatched performance at a lower weight compared to copper." This innovative wire is favored in high-efficiency motors and transformers, making it crucial for evolving energy solutions.

The benefits of Enameled Aluminum Wire extend beyond simple electrical conductivity. Its resistance to corrosion enhances durability in various applications. Additionally, advancements in insulation technology improve its thermal performance. However, some manufacturers still struggle with quality consistency. The cost of production can be high, which might deter smaller companies from entering the market.

As industries increasingly adopt green technologies, Enameled Aluminum Wire stands as a flexible solution. Its lighter weight significantly reduces energy consumption in transportation. Yet, it is vital to remain vigilant about potential market fluctuations. Balancing affordability and innovation will be key for wide-scale adoption.

Benefits of Enameled Aluminum Wire in Electrical Applications for 2026

Enameled aluminum wire is gaining recognition in electrical applications. Its lightweight nature is a key advantage. This wire can be easier to handle than traditional copper options. Reduced weight contributes to lower shipping costs as well. That is something many industries find appealing.

A notable benefit of enameled aluminum wire is its excellent conductivity. While it does not match copper, it holds up well in various applications. The enamel coating also adds a layer of protection. This protects against corrosion and damage. However, sometimes the coating can wear down, requiring careful handling.

In 2026, the push for efficiency drives demand for such materials. Users seek to optimize performance while reducing costs. Sustainability plays a vital role too. Aluminum is more abundant and less energy-intensive to produce. Yet, manufacturers must ensure quality. There is concern about consistency and reliability in the final product. Balancing these factors is an ongoing challenge in the industry.

Benefits of Enameled Aluminum Wire in 2026

Cost Efficiency of Enameled Aluminum Wire Compared to Copper Alternatives

Enameled aluminum wire has gained popularity due to its cost efficiency compared to copper alternatives. In 2026, this shift is more pronounced. Aluminum is lighter and less expensive than copper. This makes it a more attractive option for various applications, from electrical wiring to motors.

The manufacturing process of enameled aluminum wire can reduce production costs. The insulation process allows the wire to handle higher temperatures. As a result, it often performs just as well as copper in certain situations. However, it is crucial to weigh the long-term durability against initial savings. Some industries still hesitate due to perceived performance issues.

While enameled aluminum wire is cheaper, not everyone fully embraces its benefits. Concerns about conductivity and strength linger in the minds of engineers. Yet, many have found its advantages too significant to ignore. Still, further research is needed to optimize its use in demanding environments. The conversation around materials continues, highlighting the need for balance between cost and quality.

Thermal and Electrical Conductivity Improvements in 2026 Enameled Aluminum Wire

In 2026, enameled aluminum wire has witnessed significant advancements in thermal and electrical conductivity. Recent reports indicate that this wire type now achieves a thermal conductivity increase of nearly 15% compared to previous standards. This improvement allows for better heat dissipation in electrical applications. Enhanced conductivity also leads to reduced energy loss, making systems more efficient.

However, not all aspects of this development are perfect. Some users report issues with the wire's durability under high-stress conditions. Data suggests that while the improved conductivity benefits most applications, some types may struggle in extreme environments. A study found that 18% of users experienced failures when subjected to prolonged high temperatures. This indicates a need for further research and development.

Moreover, the electrical conductivity of enameled aluminum wire has improved by around 10%. This makes it a more viable option for high-performance applications. The shift towards aluminum from copper is gradually being accepted. Yet, skepticism remains due to past performance issues. As industries adapt to these changes, the balance between efficiency and reliability will be crucial for future growth.

Environmental Impact and Sustainability of Enameled Aluminum Wire Materials

The environmental impact of enameled aluminum wire is significant. This material is lightweight and recyclable, which reduces energy consumption during production. Studies suggest that using aluminum wire can save up to 70% of energy compared to copper alternatives. However, sustainability depends on proper recycling practices. Many facilities still lack efficient recycling systems, causing more waste.

Enameled aluminum wire has a smaller carbon footprint. According to recent reports, its production emits 40% less CO2 than conventional copper wire. This is crucial as industries look to meet stricter emissions regulations. Still, the challenges remain. Not all recycling processes are green. Inefficient methods can lead to pollution.

Tips: Always check local recycling options. Research your vendor's practices. Together, we can ensure a more sustainable future for enameled aluminum wire. The path to sustainability requires vigilance and commitment from all stakeholders. Is there enough awareness about recycling methods? Improvements can always be made.

Innovations in Enameled Aluminum Wire Technology Enhancing Performance in 2026

Innovation in enameled aluminum wire technology is advancing rapidly in 2026. This year, significant improvements focus on enhancing conductivity and reducing insulation weight. New coating techniques allow for better adhesion and thermal stability. These innovations lead to more efficient applications in various sectors.

Many industries benefit significantly from these enhancements. Electric motors, transformers, and coils now operate more efficiently. This is crucial for renewable energy systems and electric vehicles. However, the manufacturing process can still have inconsistencies. There are reports of defects and variable quality in some batches. These issues highlight the need for ongoing quality control.

Additionally, the versatility of enameled aluminum wire is expanding. It can now be customized for unique applications. This adaptation allows for innovative designs in electronics and telecommunications. Yet, the challenges in scaling production remain. Manufacturers must balance efficiency with quality, which is not always easy. The journey of advancement is ongoing, and reflection on these challenges can lead to even greater breakthroughs.