2026 Best Stainless Steel Wire Mesh Options and Uses?

stainless steel wire mesh has become indispensable across various industries. According to the Global Stainless Steel Wire Market report, the demand is expected to grow by 5.2% annually through 2026. This growth reflects the mesh's versatile applications, from filtration to architectural design.

Many industries adopt stainless steel wire mesh due to its durability and corrosion resistance. The automotive and aerospace sectors heavily rely on it for essential components. In construction, it serves as reinforcement. Yet, the quality varies, leading to confusion for buyers. Not all options meet industry standards.

Investing in the right stainless steel wire mesh is crucial. It can impact efficiency and safety. Buyers should reflect on their choices. Choosing low-quality mesh might lead to higher long-term costs. Achieving the best results requires careful selection and understanding of the product's characteristics.

Overview of Stainless Steel Wire Mesh Types and Specifications

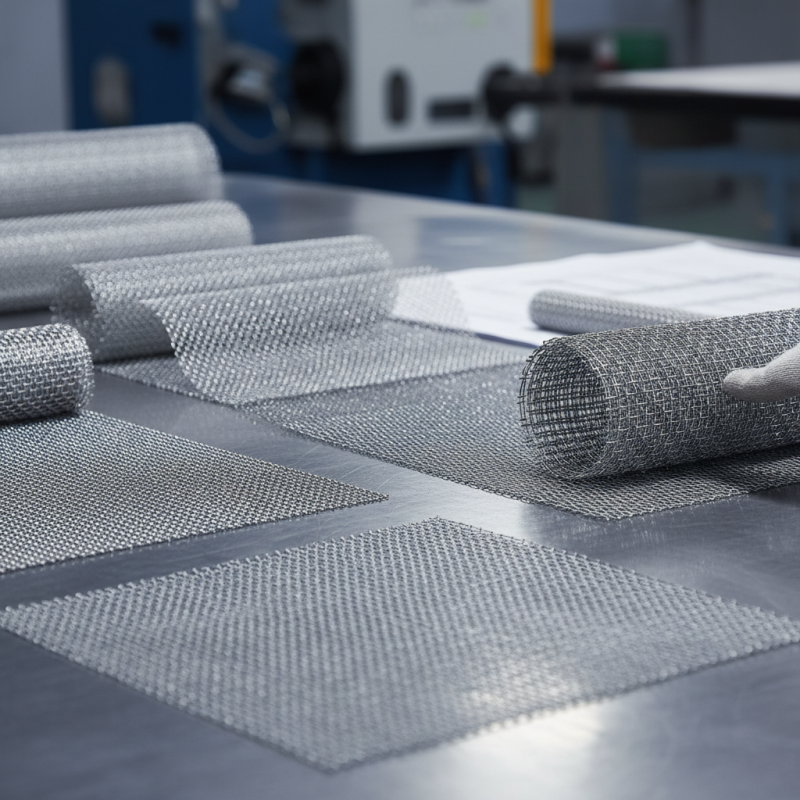

Stainless steel wire mesh comes in various types, each serving distinct purposes. The most common types include woven wire mesh, welded wire mesh, and perforated mesh. Woven mesh is durable and flexible, making it ideal for filtration and separation. Woven wire often has a tighter weave, providing enhanced strength and durability. Data from recent industry reports indicate that woven wire mesh can withstand pressures of up to 5000 PSI, making it suitable for high-demand environments.

Welded wire mesh is superb for construction and fencing applications. It ensures stability and prevents deformation over time. This type typically consists of different wire gauges. The gauges can range from 10 to 24, with heavier gauges providing more strength. Perforated mesh, on the other hand, is widely used in sound insulation and ventilation systems. Its hole patterns allow for airflow while maintaining structural integrity.

Tips: When selecting the right type of wire mesh, consider the application and environment. Ask the supplier for specifications. Check for compatibility with the intended use, as not all meshes suit every condition. Be aware of corrosion factors that may weaken the material. A careful examination of your needs can lead to better choices.

Advantages of Using Stainless Steel Wire Mesh in Various Applications

Stainless steel wire mesh offers significant advantages across various industries. Its durability is one of the most notable benefits. This type of mesh resists rust, corrosion, and extreme temperatures. It maintains structural integrity in harsh environments, making it ideal for both indoor and outdoor applications. Many factories utilize this mesh for filtration systems that require reliability.

Another appealing aspect is its versatility in design and functionality. Stainless steel wire mesh can be customized in various shapes, sizes, and patterns. It fits well in architectural designs, providing both aesthetics and security. In agriculture, it serves as effective fencing to protect crops and livestock. However, some users may find it challenging to determine the appropriate mesh size for their specific needs. The choice can significantly impact performance.

Additionally, stainless steel wire mesh is environmentally friendly. It is recyclable and reusable, reducing waste. This quality is attractive to many industries aiming to go green. Yet, the initial cost can be higher than other materials. Many users must weigh upfront expenses against long-term savings. This consideration is crucial for those on a budget, as immediate savings can be tempting.

Common Uses of Stainless Steel Wire Mesh in Industry and Agriculture

Stainless steel wire mesh plays a vital role in various industries. In agriculture, it is commonly used for fencing and screenings. Farmers often rely on it to keep pests away from crops. This ensures better yield and minimizes damage. According to industry reports, setting up wire mesh fencing can reduce pest-related losses by up to 30%.

Within the construction sector, stainless steel wire mesh enhances structural integrity. It is crucial for concrete reinforcement and is utilized in various building applications. The durability of stainless steel meshes means they can withstand harsh environments. However, the initial costs can be higher than other materials.

In the food processing industry, these meshes are easy to clean and maintain. They prevent contamination and ensure hygiene. Research shows that 25% of foodborne illnesses stem from contamination, making proper screening essential. Yet, while they offer many benefits, improper installation can lead to issues. Regular maintenance is necessary to uphold their effectiveness.

2026 Best Stainless Steel Wire Mesh Options and Uses

This chart illustrates the common uses of stainless steel wire mesh across various industries. The data indicates that construction and filtration are the leading applications, followed by food processing, agriculture, automotive, and aerospace. The percentages show the relative prevalence of each use within the industry.

Factors to Consider When Choosing Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, consider various factors that affect its performance. The wire diameter plays a critical role in strength and flexibility. Thicker wires create stronger mesh, but they may be less adaptable. For instance, a thicker mesh is ideal for heavy-duty applications, while thinner options work for lighter tasks.

The mesh opening size is another important factor. Smaller openings offer better filtration. They can prevent small particles from passing through. Conversely, larger openings allow for better airflow and drainage. Users often need to balance between filtration and flow rate based on their specific needs.

Corrosion resistance is also essential. Stainless steel types vary in their resistance to rust and oxidation. Understanding the environment where the mesh will be used is crucial. If exposed to harsh chemicals, a more resistant material may be necessary. Finally, assess the mesh's weave pattern. Different weaves provide varying levels of strength and flexibility. Inspect samples to determine which pattern best fits your application. Each choice carries its benefits and drawbacks, prompting careful consideration.

2026 Best Stainless Steel Wire Mesh Options and Uses

| Mesh Type | Aperture Size (mm) | Wire Diameter (mm) | Material Grade | Common Uses |

|---|---|---|---|---|

| Square Mesh | 1.00 | 0.5 | 304 | Filtration, Screen Protection |

| Welded Mesh | 2.00 | 1.0 | 316 | Construction, Fencing |

| Expanded Metal | 3.00 | 2.0 | 304 | Grating, Platforms |

| Perforated Metal | 4.00 | 1.5 | 316 | Acoustic Panels, Air Filters |

| Twill Weave Mesh | 0.50 | 0.25 | 430 | Food Processing, Pharmaceutical |

Maintenance Tips for Enhancing the Longevity of Stainless Steel Wire Mesh

Stainless steel wire mesh is durable and versatile. To enhance its longevity, regular maintenance is crucial. Begin by cleaning the mesh frequently. Use warm soapy water and a soft brush. This simple practice removes dirt and prevents corrosion. Pay attention to areas that accumulate debris.

Inspect the mesh periodically for signs of wear. Look for rust spots, especially in humid environments. If you find any, address them immediately. Minor repairs can extend the life of the mesh significantly. Consider applying a suitable protective coating. This can add an extra layer of defense against the elements.

Storage matters too. If the mesh is not in use, store it in a dry location. Moisture can lead to rust. Wrap it in a cloth or plastic cover. This may seem like a small step, but it makes a difference. Not everyone realizes the importance of proper storage. Neglecting these aspects can lead to premature degradation of the material. Taking these maintenance tips to heart can ensure your stainless steel wire mesh stands the test of time.